New or retrofit? Both require a heat loss calculation or damn good estimate if retrofit. Retrofits often require duct upgrades if coming from a fossil fuel furnace. What is the size of home and size of property? This determines heat pump (HP) and loop size. Bigger homes always perform better with mulitple HP’s.

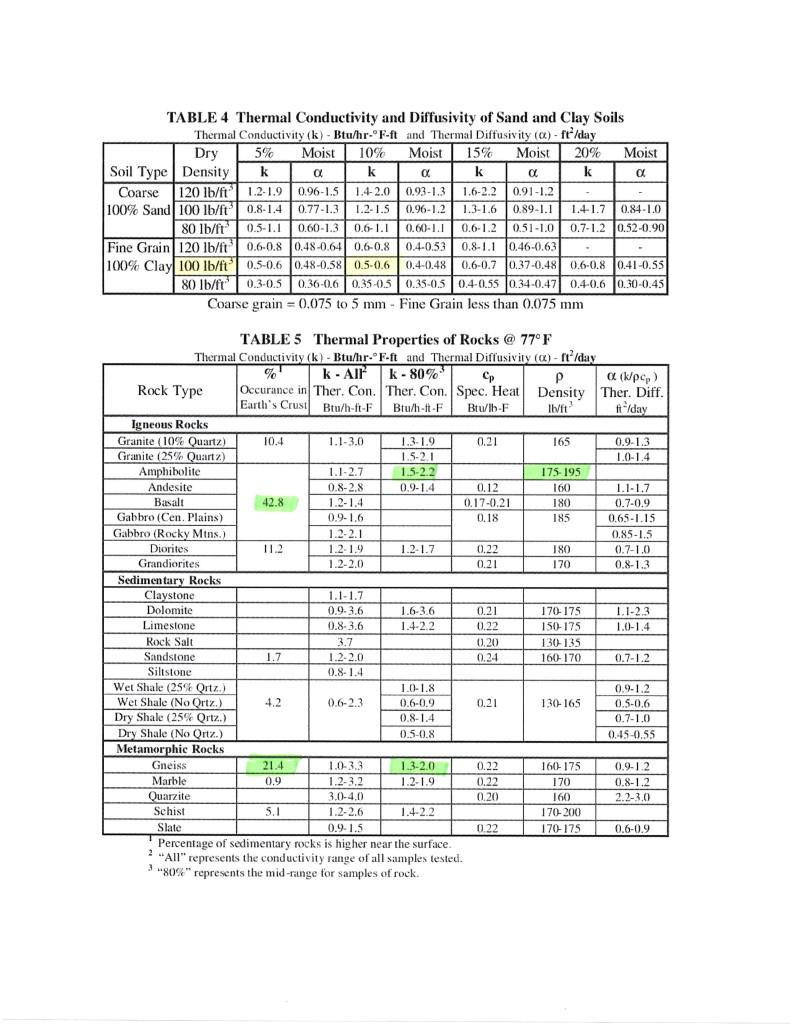

Location. Your precise address helps but often the nearest big-ish city is needed since not every little town is available for climate data. Water bodies, soil conditions, and local knowledge help too.

Forced air or radiant floors? Forced air is relatively simple but is hard to zone, radiant or hydronic systems require a mech room and many more parts but offer superior comfort and lower run costs.

Horizontal or vertical loops? Vertical is almost always better but usually more expensive but sometimes not. Deeper and fewer holes are always better. However vertical is cheaper in the very long run. Horizontals require a very large land area, anyone who says otherwise is cheating the laws of physics, good luck with that. I’m reluctant to design horizontals in an area of high cooling loads. What is the nature of the soil and subsurface? Water well drillers provide the best info here.

Geo contractor, DIY, or plumbing contractor? This question is a can of worms…..

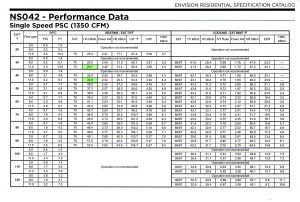

Level of technology? Some clients want the latest in connectivity and variable speed everything. Others want simple and reliable. I’ve found the best approach is simple and reliable and spend the savings from the hi tech version on a bigger loop. The bigger the loop the better, everyone seems to want to save money here but undersized loops are the biggest mistake I’ve seen in 24 years of doing this.

However, I do love to see an internet connection to view HP functioning remotely.

The Geo Guy